Save Yourself Time & Money By Getting Your Kent Peg Roof Tiles Right First Time

Our Range of Kent Peg Clay Tiles We sell

Why Choose Peg Tiles?

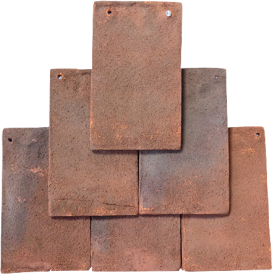

Blending into history and standing out at the same time, Spicer offers a range of tiles that are unique and uncompromisingly genuine. They also do their job magnificently and are guaranteed to do so for generations.

Each one is handmade from start to finish, and carry perfectly imperfect features such as the artisans’ fingerprints or a ‘smile’, created in the mould when excess clay is removed. A smiling peg tile is confirmation of a genuine handmade product.

History Of Kent Peg Tiles

The definitive Kent peg tile has been beautifying and protecting buildings in Britain for hundreds of years, but its prototypes go back to the Romans and beyond.

Popular production can be traced back to 1330, and in 1477 Edward IV signed a charter of standardisation. This was never entirely accepted by Kent peg producers, and to this day they range from 6 to 6.5 inches wide and 9 to 10 inches long.

Making clay tiles the old-fashioned way. Two skilled

craftsmen pose for a photo opportunity.

Jane Spicer making a batch of oast-tapered peg tiles at our first factory circa. 1992.

A horse-powered pugmill

We Use Traditional Kent Peg Tile Methods

We extrude a lug of clay, apply the desired finish to the face of the tile, either sand or sawdust, and then throw the clay into the mould, spreading it around the mould by hand.

The excess clay is then struck off using a tool made from Ash. This clay is then recycled back into the pugmill and the tile is nearly ready to be turned out onto the drying rack, but not before the square holes are punched through the tile using a tapered wooden stick whittled from off-cuts.

Tiles are dried for 2 days and then loaded onto a shuttle kiln by hand where they are burnt for 24 hours and cooled for a further 18.

Our method of firing encourages variance in our colours, shades and shapes which make for a fantastic blend on a roof. Within the kiln we get hot and cold spots, with all the varieties in between.

The only thing we don’t do anymore is use a horse to turn the pugmill.

Results Our Customers Loved

Our mission is the keep production of Kent Peg Tiles alive for decades or centuries to come. We have a heavy focus towards conservation and restoration projects throughout the South-East. We encourage factory tours and take pride in exhibiting our production methods. If this is something you are interested in please contact our office on 01797 364777 or fill out our contact form here.

Spicer Red Antique Peg tiles on the vertical and Medium Antique Peg tiles on the main roof of this beautiful property in the heart of Charing, Kent.

Bespoke size colour Peg tiles were made for this project at the Weald & Downland Museum in West Sussex.

Pallingham Quay was a restoration project of a cart shed originally built in the early-mid 1800’s.

Please click here to see the full case study of Pallingham Quay.