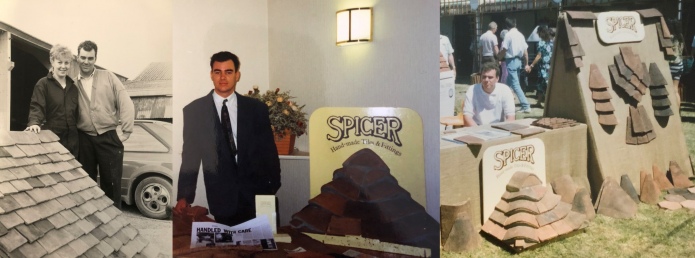

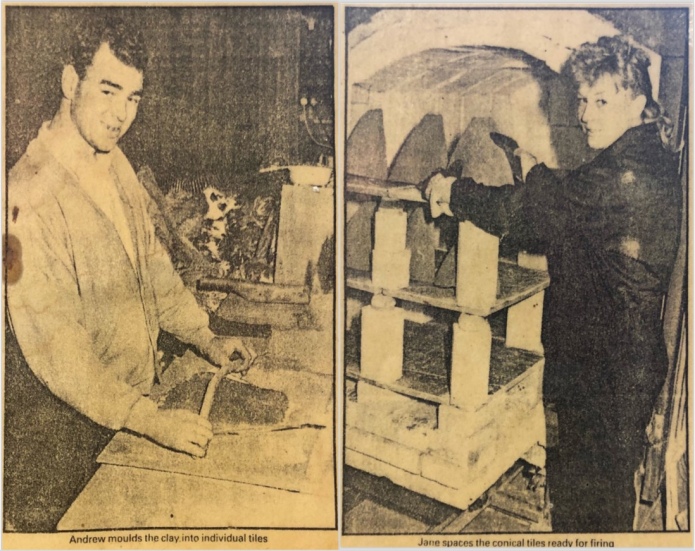

Spicer Tiles gained its matchless reputation by producing and supplying genuine handmade clay tiles of quality for 35 years. Now, Spicer Tiles closely monitors the production of all of its products from factories around the world, paying close attention to quality, production processes, responsibly practices, staff well-being, and environmental sustainability. Choosing a genuine handmade clay roof tile is a sure sign of care and consideration to your project.

To date the Spicer family still play an active role in the business, instilling the mantra of ‘imperfect, but perfect’ in all our ventures.

Timeline

1960

1979

1987

1988

1989

1990

1991

1994

1999

2011

2012

2013

2014

2017

2018

2022